Our Blog

Check out our innovative pump solutions and industry insights to see what's new in the pumping industry. Stay up to date with the latest trends and news in the world of pumping technology by following our pumping technology blog.

- Home

- Blog

2026 How to Choose the Right 2 Submersible Pump for Your Needs?

Choosing the right 2 submersible pump can be daunting. You must consider various factors. An expert in the field, John Smith, once said, "Select a pump that matches your specific requirements to avoid frustration."

2 submersible pumps come in different sizes and capacities. They are used for various applications, from dewatering to irrigation. Identifying your needs is crucial. A mismatch can lead to inefficiency or even pump failure. Many overlook the importance of pump materials and durability.

Not all pumps are created equal. Some may claim to offer high performance, but their long-term reliability is questionable. It's vital to reflect on your choices. A well-chosen 2 submersible pump can save time and effort down the line. Take the time to research and evaluate your options carefully. Your future projects depend on it.

Understanding Submersible Pump Types: A Comprehensive Overview

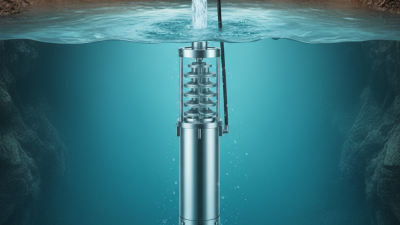

When selecting a submersible pump, understanding the types available is critical. There are several types designed for various applications. The most common are sewage pumps, drainage pumps, and deep well pumps. Each serves a specific purpose.

Sewage pumps handle waste material.

Drainage pumps are ideal for emptying water from flooded areas.

Deep well pumps draw water from underground sources.

Tips: Consider your specific needs before choosing a pump. Evaluate the depth of the water source. What is the water's viscosity? These factors influence pump performance.

Another essential detail is the pump's material. Some pumps are made of stainless steel, while others use thermoplastic. The choice of material affects longevity. A well-chosen pump can save money and frustration down the line. However, many overlook these details in the selection process. Remember, not all pumps fit every situation perfectly. You might find yourself needing to replace a poorly chosen pump sooner than expected.

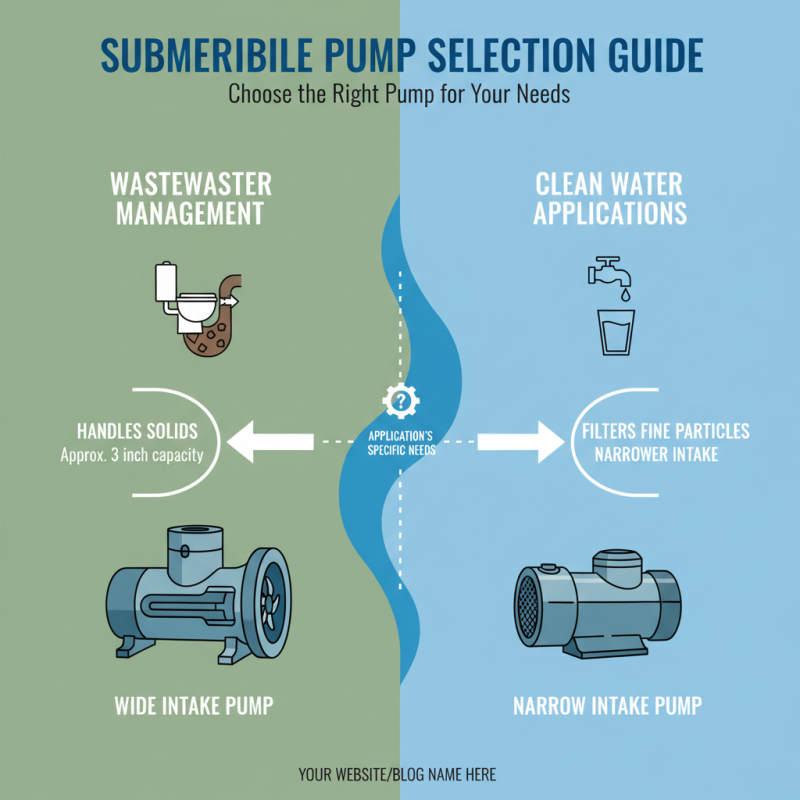

Key Factors in Selecting a Submersible Pump for Different Applications

When selecting a submersible pump, consider your application's specific needs. Different tasks require varying pump capabilities. For example, wastewater management often demands pumps that can handle solids, which are typically around 3 inches. Conversely, for clean water applications, a pump with a narrower intake is more suitable.

According to recent industry reports, over 75% of submersible pump failures occur due to incorrect sizing. This highlights the importance of understanding flow rates and head requirements. For residential uses, a flow rate of 10 to 30 gallons per minute may suffice, while industrial applications could require flows exceeding 100 gallons per minute. A mismatch can lead to inefficiency and costly downtime.

Additional factors include the pump's material. Corrosion-resistant materials are crucial in harsh environments. Yet, many users overlook this, leading to premature wear. Noise levels are another consideration. Some pumps operate quietly, making them ideal for residential areas. Disregarding these details may result in dissatisfaction and a need for reevaluation down the line. Proper research and consultation can aid in making the right choice.

Assessing Required Pump Capacity: Flow Rate and Head Calculations

When choosing a submersible pump, understanding flow rate and head calculations is crucial. Flow rate measures how much water the pump can move in a given time. It’s often expressed in gallons per minute (GPM) or liters per minute (LPM). For instance, if you need to drain a flooded area, think about the size and depth of the water. This will affect how quickly you need to remove the water.

Head calculation helps you understand the height to which water needs to be lifted. This measurement is vital if your pump is going to be submerged in deep wells or cisterns. If the pump doesn’t have enough head, it won’t perform efficiently. Picture a scenario where your pump struggles to reach its full potential. It might leave standing water behind, leading to unnecessary complications.

Choosing the right pump isn’t just math. It involves considering your specific situation. Each application is unique, with its own challenges. Maybe you think one option will work, but the calculations suggest otherwise. This discrepancy calls for reflection and adjustment. It’s important to track your needs accurately to find the most efficient solution.

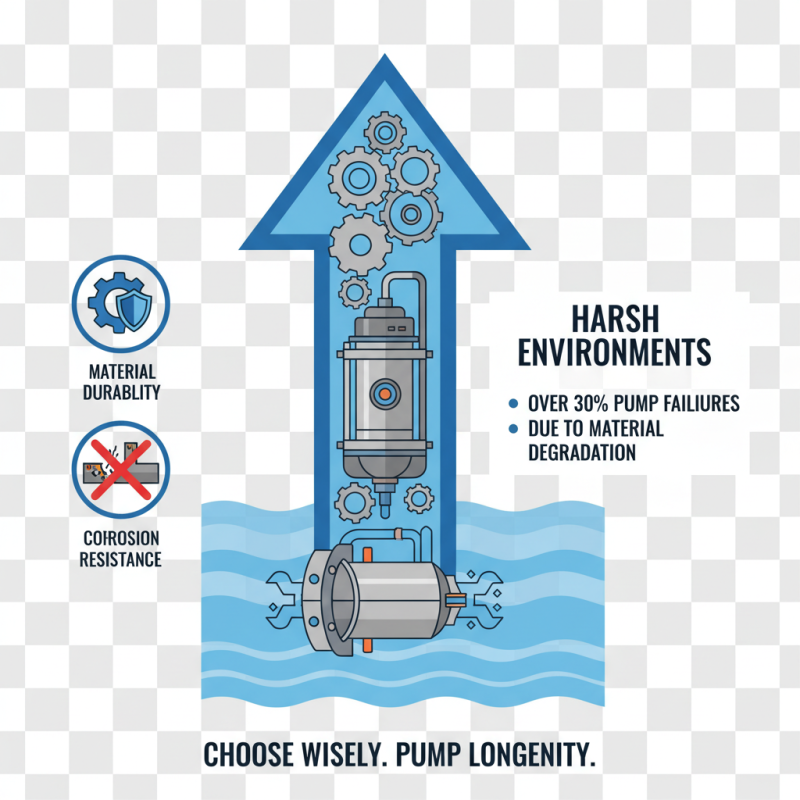

Evaluating Material Durability and Corrosion Resistance Standards

Selecting the right submersible pump involves understanding material durability and corrosion resistance. Many pumps operate in harsh environments. A report from the American Society of Mechanical Engineers highlights that over 30% of pump failures are due to material degradation. Therefore, choosing the right materials is crucial.

Stainless steel is commonly favored for its corrosion resistance. However, it's essential to note that not all stainless steel grades perform equally. For instance, 316L stainless steel outperforms 304 in salty or acidic conditions. According to industry data, pumps made from 316L can last up to 15 years in corrosive environments, while those made from lesser materials may fail within 3-5 years.

Another factor to consider is the coating of the materials. Epoxy coatings can enhance the lifespan of submersible pumps. They provide an extra layer of resistance against chemical attacks. The right coatings can increase service life by up to 25%. However, not all coatings are effective. Testing is needed to ensure compatibility with specific fluids. Submersible pump applications are diverse, and attention to material standards is vital for optimal performance.

Maintaining Submersible Pumps: Best Practices and Lifespan Expectations

Maintaining submersible pumps is crucial for their longevity and efficiency. A proper maintenance plan can extend a pump's lifespan by 30% or more. Regular inspections are essential. Check for leaks, corrosion, or unusual noises. Neglecting these signs can lead to costly breakdowns.

Keeping the pump clean is vital. Sediments can clog the intake screen and impact performance. Industry studies show that dirty pumps can lose up to 20% efficiency. Implementing a cleaning schedule helps prevent this. Resetting the pump’s settings after maintenance allows it to function optimally again.

It's essential to monitor operating conditions closely. Water temperature or pH changes can affect performance. Many users overlook these factors. Data indicates that pumps can underperform if not appropriately calibrated. Hence, routine checks are not merely recommended; they are necessary. Regular maintenance will save time and money in the long run.

Submersible Pump Performance Comparison

Related Posts

-

2025 How to Choose the Best Submersible Well Pump for Your Water Needs

-

Exploring the Benefits and Applications of 2 Submersible Pumps in Modern Water Management

-

Maximizing Efficiency: How Submersible Pumps Revolutionize Water Management in Agriculture

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Motor Pump for Your Needs

-

Exploring the Efficiency of Submersible Water Pumps: A Comprehensive Guide for Homeowners

-

What is a Submersible Well Pump and How Does It Work?